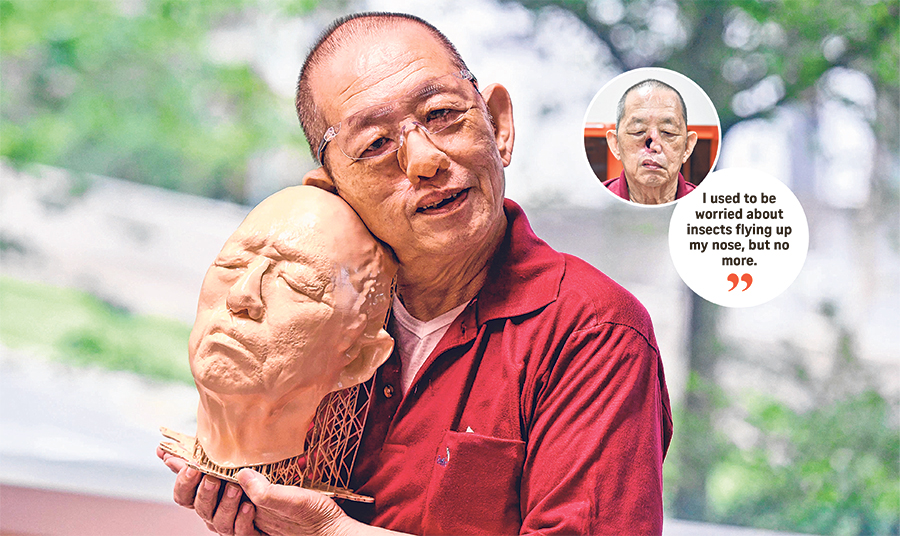

Mr J.F. Lian, 73, wearing his new 3D-printed prosthetic nose and holding a 3D-printed replica of his face that was created from pre-operation CT scans. The retiree had most of his external nose removed after radiotherapy failed to fully treat a tumour there. While some opt for cosmetic reconstruction during surgery with tissue taken from the arm, Mr Lian could not, as there was a risk that the cancer would recur. ST PHOTOS: DESMOND FOO

Mr J.F. Lian, 73, wearing his new 3D-printed prosthetic nose and holding a 3D-printed replica of his face that was created from pre-operation CT scans. The retiree had most of his external nose removed after radiotherapy failed to fully treat a tumour there. While some opt for cosmetic reconstruction during surgery with tissue taken from the arm, Mr Lian could not, as there was a risk that the cancer would recur. ST PHOTOS: DESMOND FOO

The pilot project of almost four months at Tan Tock Seng Hospital offers hope for people in need of custom-designed prostheses.

The Straits Times (15 March 2023)

When retiree J.F. Lian had most of his external nose removed in 2022 while battling skin cancer, he was resigned to living with a hole in the middle of his face.

But the 73-year-old was then offered the chance to receive a 3Dprinted nose that would be practically identical to the original organ.

Other patients who undergo similar surgery can opt for cosmetic reconstruction of the nose using tissue from the arm. However, in Mr Lian’s case, doctors were concerned that skin cancer could recur in the region and he would require surgical removal of the cancerous cells again.

Another option would have been to wear a plastic prosthesis on his face.

But Tan Tock Seng Hospital (TTSH) had a novel solution. In November 2022, TTSH’s Medical 3D Printing Centre offered to custom-design and 3D-print a prosthetic nose made of plastic or resin for Mr Lian, based on scans of his face. The hospital believes it is the first 3D-printed nose made in Singapore.

Mr Lian was intrigued. Though unfazed by the stares he often received while walking around without a mask, the former technician was willing to try the new technology.

On March 7, after nearly four months of fittings and redesigns, he walked out of the hospital wearing a nose reconstructed from scans of his face and hand-painted to match his skin. “I love the skin tone,” says Mr Lian, who is not married, has no children and declines to give his full name.

The nose is attached to his face with transparent tape and he plans to wear it while sleeping too. “I used to be worried about insects flying up my nose, but no more,” he says.

The success of this pilot project offers hope that other patients may be able to receive prostheses that look like the original organs, and which are custom-designed for their bodies and needs.

TTSH has other projects in the works, including a 3D-printed prosthetic finger.

Dr Lim Ming Yann, senior consultant and head of otorhinolaryngology (ear, nose, throat) at TTSH, says perhaps only two patients a year might need a large portion of the external nose removed for medical reasons. He says that for such patients, prosthetic noses help give them the confidence to engage socially.

He recalls a patient who opted for reconstruction of the external nose using his own tissue. The challenge with such surgery is making the new nose look good. “The advantage of 3D printing is it gives us the chance to replicate the patient’s nose, rather than a construct of what the surgeon thinks a nose should look like,” says Dr Lim.

However, designing and printing a prosthetic nose that looks like the real thing is not easy, even with access to 3D images of what the patient looked like before surgery.

Among the challenges are working with the patient to ensure a proper fit and painting the prosthesis to match the user’s skin.

3D Medical Printing

TTSH’s Medical 3D Printing Centre was officially opened in November 2022, but has been in operation since 2020.

It prints models of patients’ organs from medical scans, so the attending doctor can better explain their condition and what treatment they need.

Surgeons also use the centre to print jigs or custom tools to aid in surgery, or models to practise complex procedures on.

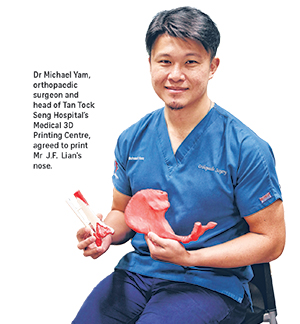

Dr Michael Yam, orthopaedic surgeon and head of TTSH’s Medical 3D Printing Centre, first used 3D printing to assist in surgery in 2019.

He got a model of a patient’s pelvis made from computerised tomography (CT) scans to prepare for a tricky operation and reduce guesswork while the patient was on the operating table.

“In the past, we had to estimate and think: ‘Am I already at the right spot?’

“With 3D printing, you can think of a solution before you even operate on a patient, which is beneficial,” says Dr Yam.

He adds: “When it comes to complex fractures, 3D prints are also great for teaching a patient where we are going to place a metal plate or a screw.”

As word spread about the usefulness of 3D printing, print requests increased.

Now, there are eight printers in the centre – costing between $6,000 and $10,000 each – which handle around two or three requests a day, or 10 a week. 3Dprinting engineers from an external company, Medairum, are seconded to the centre to deal with print jobs.

Dr Yam says: “I know how useful 3D printing can be, and I’m always looking to push the boundaries.” So when a colleague suggested that the centre design and print a prosthetic nose for Mr Lian, he agreed.

Custom Job

The first step was creating a 3D print file for use. This was derived from CT scans taken of Mr Lian’s face before surgery.

The images were cleaned up by the 3D-printing engineers and “sliced” into files that the printer could read.

It took about an hour for the nose to be printed – more complex medical models can run up to 100 hours – after which it was cured, or made solid, and then smoothed and polished.

Once a prototype was complete, Mr Lian came in for a fitting. The 3D-printing team found that he had lost weight and the shape of his face had changed, so the nose no longer fit well.

They had to rescan his face, using a handheld scanner to map its topography.

The next prototype looked better, but still looked nothing like a nose. 3D printers could not print realistic colours.

ST PHOTOS: FELINE LIM, KEVIN LIM

ST PHOTOS: FELINE LIM, KEVIN LIM

Make-up Magic

Dr Yam was stumped, until a colleague suggested working with cosmetic experts from the Institute of Technical Education (ITE) to make the nose more lifelike.

He sent an e-mail to ITE College East’s section head of the beauty and wellness course, hoping for the best.

Ms Jessie Goh nearly declined, she told The Straits Times. “I had to think about this very hard,” she says.

Ms Goh has years of experience doing stage and special effects make-up, including making realistic gunshot wounds. However, painting a prosthesis was new to her and she worried whether she would be up to the challenge. “The kind of work we do is meant to last only a few hours or a day, but this nose is for daily use.”

She roped in her colleague Ho Ee Na, a lecturer in the same department, for input.

The two began by experimenting with different types of cosmetic paints and found that their usual arsenal did not work well.

Madam Ho says: “We thought it would be easy, but it was not. It’s very different. When we do makeup, we blend colour on a person’s skin. The paint sits very differently on the prosthetic nose.”

Like many 3D-printed items, it is made of resin.

They met Mr Lian five times at the Medical 3D Printing Centre to work on getting the right skin tones, mixing layers of skin-safe acrylic paint to get a light beige colour that matched his face.

Then came painting fine details such as pores and capillaries as well as shading the nose, followed by a clear sealer or finishing coat.

The two cosmetic experts then worried about what would happen if Mr Lian tanned in the sun. Their only solution for now is asking Mr Lian to stay in the shade.

Another concern was making the nose to fit Mr Lian’s face. At one session in February attended by ST, Mr Lian asked the 3D-printing engineers to redesign the nose with a small hook that could fit into his nasal cavity.

They did, but that prosthesis turned out to be uncomfortable for prolonged use.

Finally, Mr Lian hit upon the idea of transparent skin-safe sticky tape. He also bought two pairs of spectacles to cover the area where the prosthesis meets the face.

On March 7, the make-up experts put the finishing touches on Mr Lian’s nose and he posed for photographs while smiling broadly. “I really love it,” he says. “It’s quite light, I don’t feel like I’ve got anything on.” Dr Yam and the 3D-printing team are ready for the next batch of prostheses.

"I think we can roll this out as a service for all patients who need nose prostheses,” Dr Yam says, adding that the hospital would have to work out the cost of this service. Mr Lian received his for free, since it was a pilot project. Ms Goh and Madam Ho hope to be back with students to work on making other prosthetics look real. Ms Goh says: "It will be a good thing for our students to do this because it’s so meaningful. Our students don’t know that being a make-up artist or a therapist can be so meaningful – not just beautifying people, but also helping them."

Madam Ho agrees. She adds: "If we continue to collaborate on this, then we will have to look out for paints other than acrylic. I hope to find other paints that are more translucent, so I don’t need to spend so much time blending them."

Two inventions tapping 3D printing are helping Tan Tock Seng Hospital (TTSH) patients, such as those who have lost their fingers or part of their skulls, in their recovery journey.

Read more